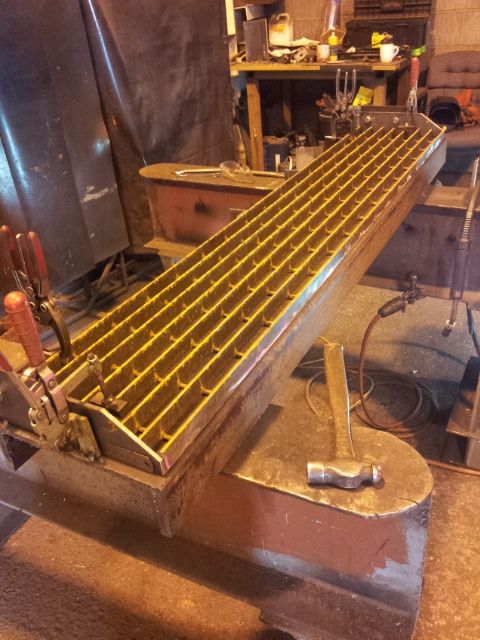

Firstly i made a jig the width of the steps, I used a bit of offcut channel and a few clamps

Then i made some end plates out of 80mm x 6mm and punched 2 x 14mm holes for the M12 bolts

The flow forge grating i cut to width using a grinder and a cutting disk, To cut the length i took the full length of grating and cut it on the bandsaw. Its quicker easier and cuts it nice and square

next we need to put the end plates on the jig, i used bolts to hold them flat and upright,

Then stick the grating in there, make sure that you have the top face on the bottom, its easy to get confused

Now we need to tack the tops of the flats all way along both sides

When its done both sides we take it out from the jig and get ready to weld the flats

And this is what it looks like welded up, Some people weld both sides but i just weld one side, Thats plenty strong enough.

Tack the tops of the flats

and then sand flush

And there you have it, so easy and far cheaper than buying ready made

You can make an imporovement by add a 3mm durbar strip along the frond end, to act like a non slip tread

No comments:

Post a Comment